Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

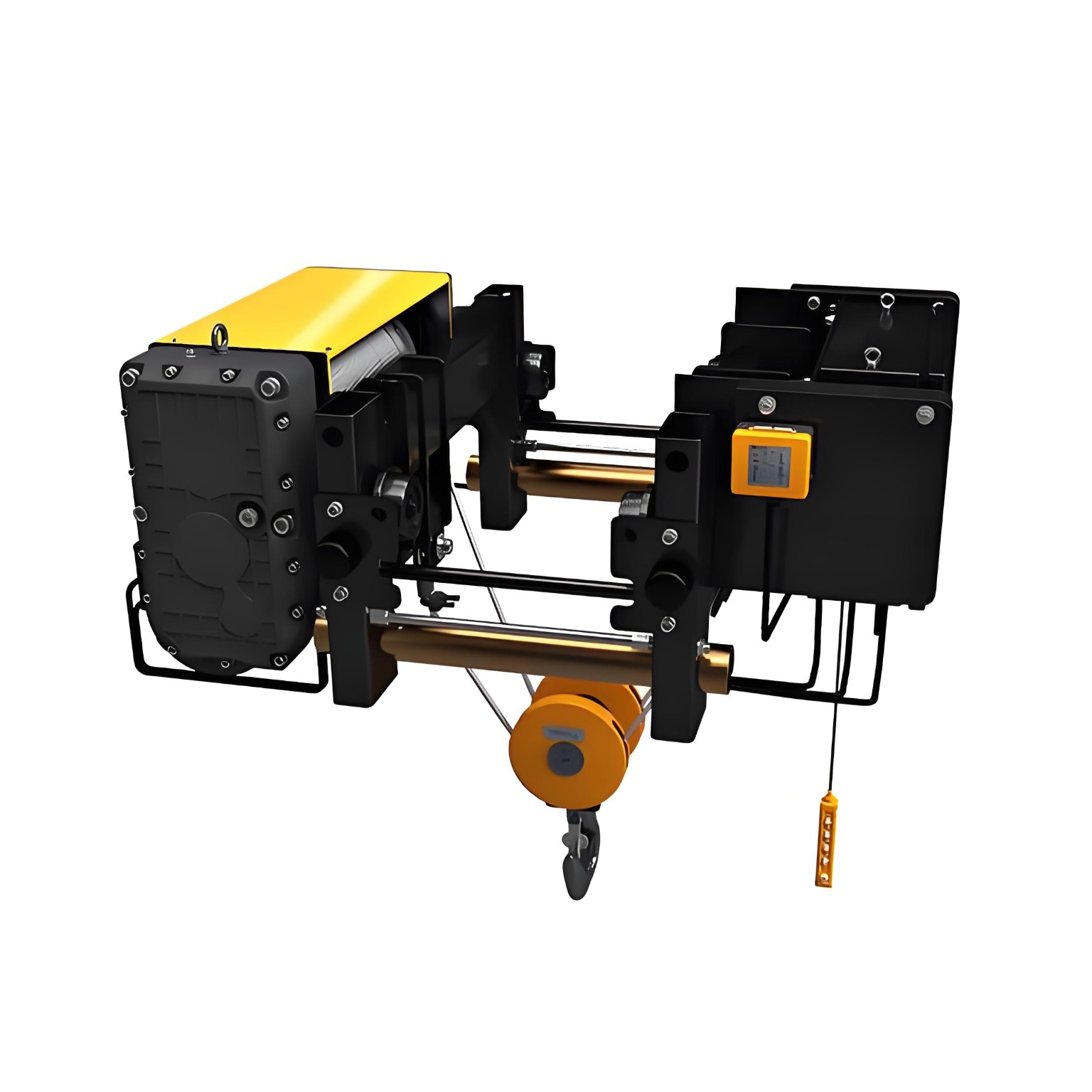

Our European-style electric hoist is a lightweight, modular, and maintenance-free electric hoist developed by our company based on the introduction and digestion of international technologies, utilizing imported components, new materials, and advanced processes. It utilizes a hoisting motor and reducer imported from Germany. The integrated, compact design of the hoisting motor, reducer, drum, and hoisting limit switch saves space. The modular design enhances reliability while effectively reducing maintenance time and costs. It offers a wide range of lifting speeds and a variety of pulley ratios.

Drum:The drum is machined from high-quality seamless steel tube using CNC machines. The precision-machined grooves on the drum, combined with a rope guide, effectively prevent rope loosening and tangling.

Wire Rope:The wire rope utilizes high-strength imported steel wire rope with a tensile strength of 2160 N/m², ensuring excellent safety and long service life.

Rope Guide:The standard rope guide is made from wear-resistant, self-lubricating engineering plastic, significantly reducing wear on the wire rope, the primary load-bearing safety component, thereby enhancing the safety of the hoisting mechanism. Heavy-duty rope guides made of ductile iron are also available to meet specific application requirements.

Hoist Motor:The hoist motor uses a double-winding squirrel-cage pole-changing motor, achieving a 1:6 speed ratio. The motor housing is made of drawn aluminum alloy, providing excellent heat dissipation. A fan is installed at the end of the hoist motor for enhanced cooling. All hoist motors have thermistors (or thermal switches) embedded in the windings to prevent possible motor overheating.

The motors have Class F insulation and IP54 protection.Variable-frequency hoist motors can be equipped with an encoder, typically mounted directly on the fan shaft end of the motor.

Technical Features:

Low starting current, high torque

Soft start, excellent acceleration

Long design life

Technical parameters meet FEM and HMI standards

High speed, low noise

The reducer housing is constructed of lightweight, corrosion-resistant aluminum alloy. A semi-grease-based lubricant within the fully sealed housing ensures adequate lubrication of all gears, eliminating the need for lubricant changes within the designed safe operating life.

Each gear is surface-hardened and precision-ground to ensure smooth operation.

Technical Features:

Compact size, light weight

Smooth operation, low noise

Corrosion-resistant, maintenance-free